Calendering process of smoothing and compressing a material notably paper during production by passing a single continuous sheet through a number of pairs of heated rolls.

Calendared vinyl definition.

The films when cooled generally range in thickness between 70 100 micron.

By molly waters technical specialist avery dennison graphics reflective solutions.

With textiles fabric is passed between calender rollers at high temperatures and pressures.

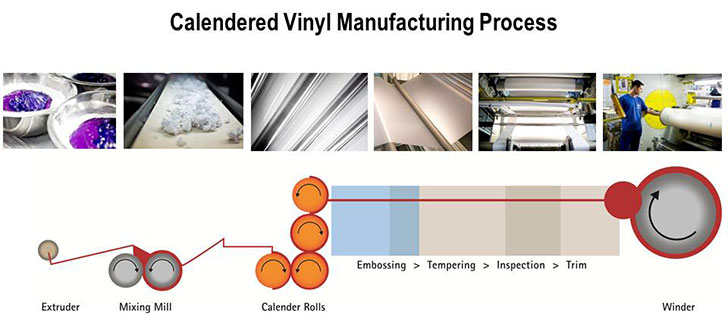

Calendered vinyl is made by extruding a heated mixture through calendering rollers.

Into paint by the use of a solvent.

In preparation for calendering the fabric is folded lengthwise with the front side or.

Learn the differences and why to use the right vinyl in the right application.

The rolls in combination are called calenders.

This method uses temperature and pressure to create a vinyl film at a specific thickness and offers speed of production for economic advantages making calendering common when producing economy grade vinyl.

Avery dennison also offers a wide range of calendered films that can be used for a variety of applications both calendered and cast vinyl films are made from the same raw materials.

The core ingredients of all vinyls are the same but the manufacturing process and additives can differ.

The basic ingredients are the same but the manufacturing process and type of plasticizers used result in significant differences.

Calender rolls are constructed of steel with a hardened surface or steel.

The manufacturing process of calendered vinyl is much faster then that of cast vinyl and this ensures bulk production at a lower cost.

The two most common types of vinyl in the graphics industry are cast and calendered.

Calenderingof polyvinyl chloride pvc formulations is the most common method of producing vinyl films.

A quick read through this article will help you understand all the ins and outs of calendered and cast vinyl.

Calendering of textiles is a finishing process used to smooth coat or thin a material.

Within the vinyl industry cast film has long been associated with quality whilst calendered film was a budget option the choice for those who didn t have much money to spend.

Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens.

Cast films are considered the industry premium.

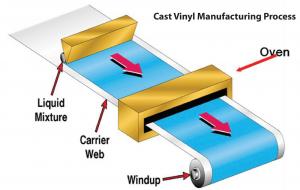

Cast film is produced by first turning the ingredients of the finished film.

However this view is rather short sighted failing to take into account any of the other aspects about calendered and cast film.

Pvc resin plasticizer colorant etc.

Vinyl film the workhorse of many print shops can be produced as either a cast or calendered film.