Because i ve already googled myself so i m asking for someone that s had success with strong bonding between anodized aluminum surfaces or bare aluminum surfaces not just someone to tell me to use super glue because you think it will work.

Bonding rubber to anodize aluminum.

Anodized aluminum is an electrolytically induced passivation process where several physical changes occur to the surface including.

I do not know for sure what kind of rubber it is but it is black and happens to be electrically conductive.

It is very flexible and soft.

Question we re having a problem with glue not adhering to anodized parts made from extruded 6063 t6 aluminum and finished with heavy etch and black anodize per mil a 8625 type ii class 1.

Aluminum alloy part w anodized surface 2003.

We prefer the glue to be dried in ambient temperature.

George zafiropoulos kallithea athens greece.

Thicker aluminum oxide layer increased porosity and increased strength brittleness.

10 31 2019 12 54 pm 2.

The anodic coating is integral to the base metal and the porous anodic film is wondrously receptive to primers and adhesives.

We are seeking a type of glue to bond aluminium parts in fact we have aluminium strips and we want to bond them with aluminium tubes.

Anodizing for pre prep bonding bridges the gap between the metallic and composite worlds as it provides a superior surface in many applications on aluminum components for bonding to these composites.

For very high strength use a metal bonder such as 170 or the original 910.

Historically several bonding methods have been employed within the rubber industry in an effort to achieve a dependable and durable rubber to metal bond.

Recommending electrical bonding techniques is outside the scope of the service that metal finishings ltd offer but below are some of the approaches that are common.

The problem parts come in batches something like a 25 50 fallout rate when we normally have about 0 5 1 fallout.

Modern adhesive technologies utilize both singleand two coat adhesive formulations with the preference depending upon the service needs of the bonded assembly.

Although aluminum is a common bonding substrate for epoxy anodized aluminum can present its own set of bonding problems.

Before gluing i rough the rubber with 150 sandpaper.

All grades will bond aluminum well.

The problem is no glue will stick to the aluminum not even gorilla glue very well.

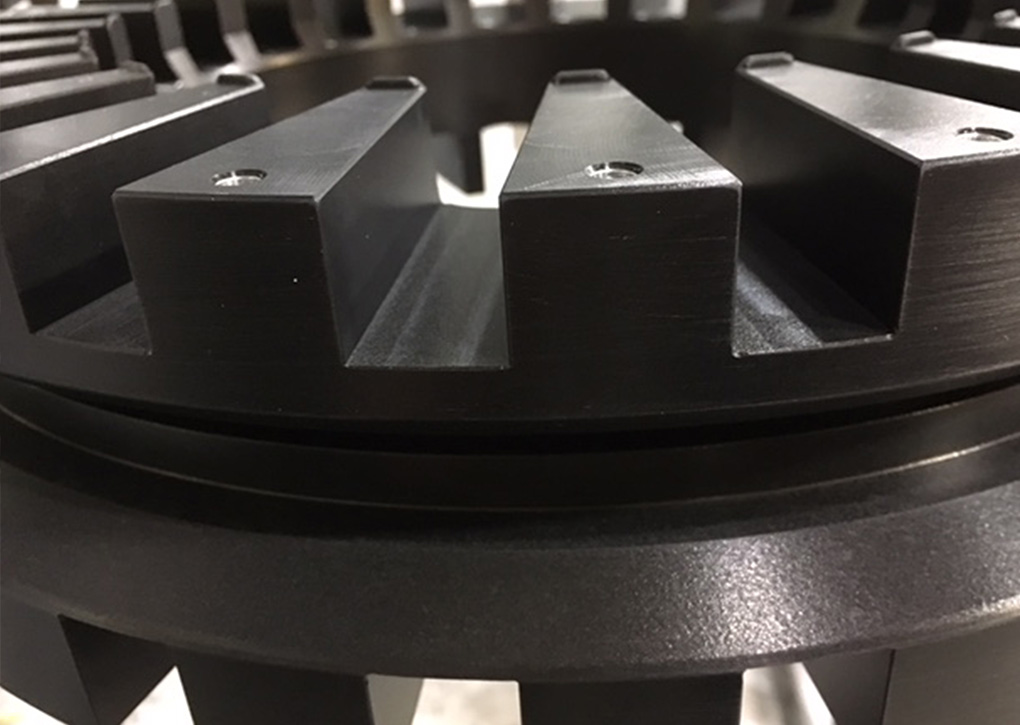

Mating faces electrical bonding is achieved by having a flat face on each part of the assembly that mates with another part.

Bonding anodized aluminum 3m vhb tape and primer ipa only primer 94 primer ap111 anodizing provides higher strength bonding with epoxy than simply abrading bare aluminum strength retention of epoxy bond is very good anodizing provides a great surface for 3m vhb tape adhesion psa tape previous testing.